- Home

- Product

- Solution

- Brand Products

- About

- News

- Contact Us

- Language

Call Anytime

18929567376

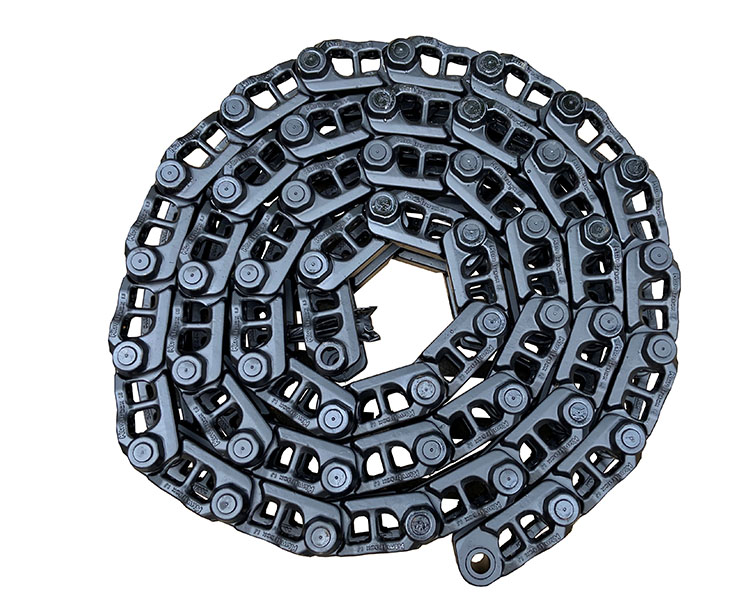

The excavator chain rail is an important component of the excavator walking device, which carries the weight of the excavator and provides necessary mobility during the operation process. The following is a detailed introduction to the excavator chain rail: 1. Structural composition. The excavator chain rail is mainly composed of chain plates, chain pins, a connecting chain piece, a second connecting chain piece, and other parts. These parts are connected together through a specific connection method (such as a chain pin cooperating with a connecting chain piece and a second connecting chain piece) to form a chain rail link, thus forming a complete chain rail structure.

2、 Strong load-bearing capacity: The excavator chain rail needs to bear the entire weight of the excavator, so it must have sufficient load-bearing capacity. This requires that the material and structure of the chain rail must be sturdy and durable to ensure stability and reliability even in harsh operating environments. Good wear resistance: Excavators need to move frequently during operation, and friction between the track and the ground can cause wear. Therefore, excavator chain rails must have good wear resistance to extend their service life and reduce maintenance costs. Strong adaptability: Excavators usually need to work in various complex terrains and operating environments, so chain tracks must have good adaptability. This requires the chain track to be able to adjust according to different ground conditions to ensure the stability and mobility of the excavator.

3、 Type and specifications

There are various types and specifications of excavator chain rails to adapt to different models and specifications of excavators. Common types include standard chain tracks, reinforced chain tracks, etc. In terms of specifications, they are mainly determined based on the weight, size, and operational requirements of the excavator. For example, for heavy excavators, it is usually necessary to choose chain rails with stronger load-bearing capacity and better wear resistance.

4、 Maintenance and upkeep

In order to ensure the normal operation and prolong the service life of excavator chain rails, regular maintenance and upkeep are necessary. This includes checking the wear of the chain rail, fastening the connectors of the chain rail, cleaning up debris on the chain rail, etc. In addition, it is necessary to regularly lubricate and replace severely worn parts of the chain rail according to the working environment and the usage of the excavator.

5、 At present, the excavator chain rail market is showing a diversified development trend in terms of market status and development trends. On the one hand, with the continuous advancement and upgrading of excavator technology, the material, structure, and performance of chain rails are also constantly improving; On the other hand, the demand for excavator chain rails in the market is constantly increasing, especially in areas such as infrastructure construction and mining. In the future, the excavator chain rail market will continue to maintain a growth trend, while paying more attention to product innovation and quality improvement.

In summary, the excavator chain rail, as an important component of the excavator walking device, plays a crucial role in the operation process of the excavator. By understanding its structural composition, functional characteristics, types and specifications, as well as maintenance and upkeep knowledge, it is possible to better select and use excavator chain rails, thereby improving the efficiency and stability of excavator operations.